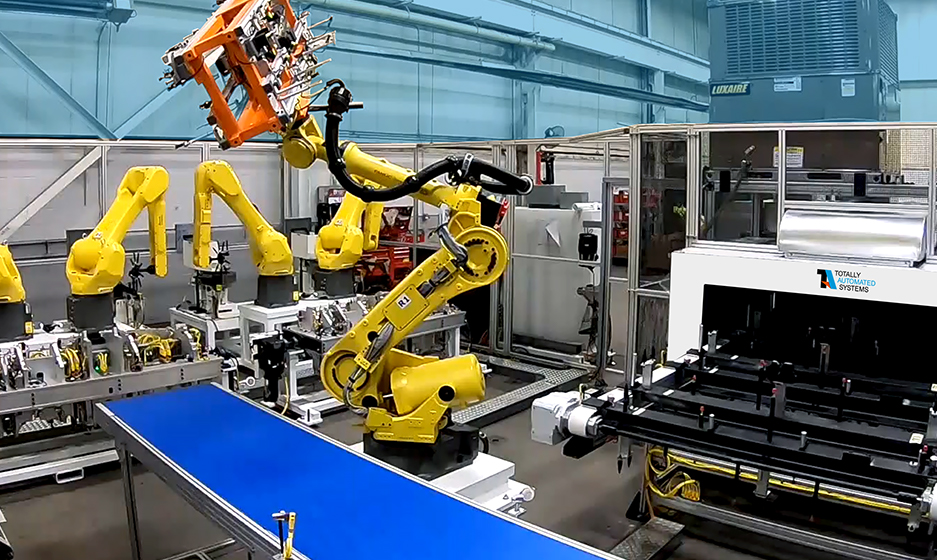

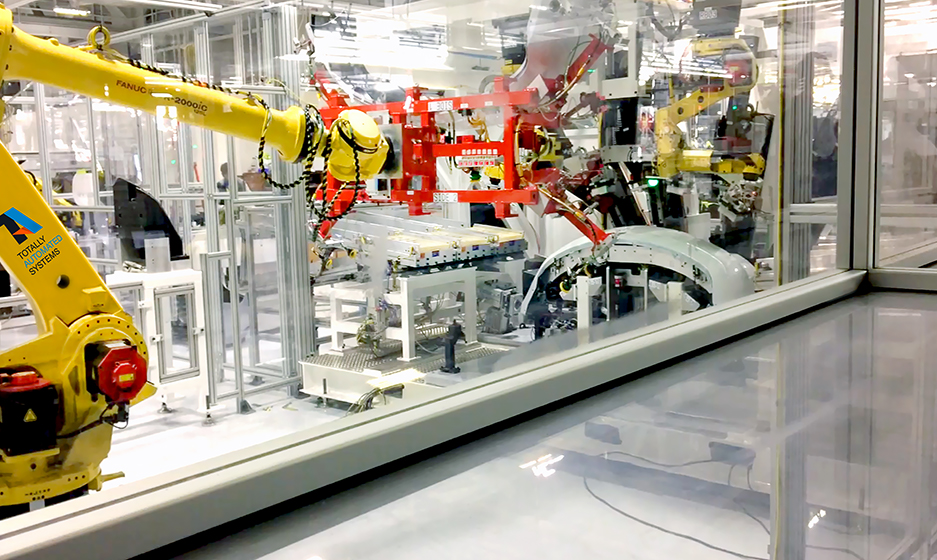

Integrated Material Handling

TA Systems has been a leader in Integrated Material Handling Solutions for over 45 years. Our capabilities encompass all aspects of not only design, engineering, and integration but also, support.

First, we partner with our customers to help determine their goals as well as objectives. Second, we design and implement the plan to achieve them. And finally, we support our customers post installation needs.

The three main characteristics of an integrated material handling system are cohesion, coordination and connectivity. The objective of a successful solution is to achieve the continuous flow of materials throughout the full process of the system. This is done by incorporating not only machines, products, and practices but also, connecting the system to warehouse or inventory control solutions.

Solutions consist of the design and implementation of an automated manufacturing system that provides a complete and timely handling process. Material Handling and Integration incorporates not only machines, products, practices but also processes.

The benefits of Material Handling and Integration include: Faster Delivery, Reduction of Excess Inventory, Lower Handling Costs, Real-Time Monitoring which allows for better Inventory Management and Accuracy of Information, Improved Customer Service, and finally, Promotion of Safety and Better Working Conditions