Project Description

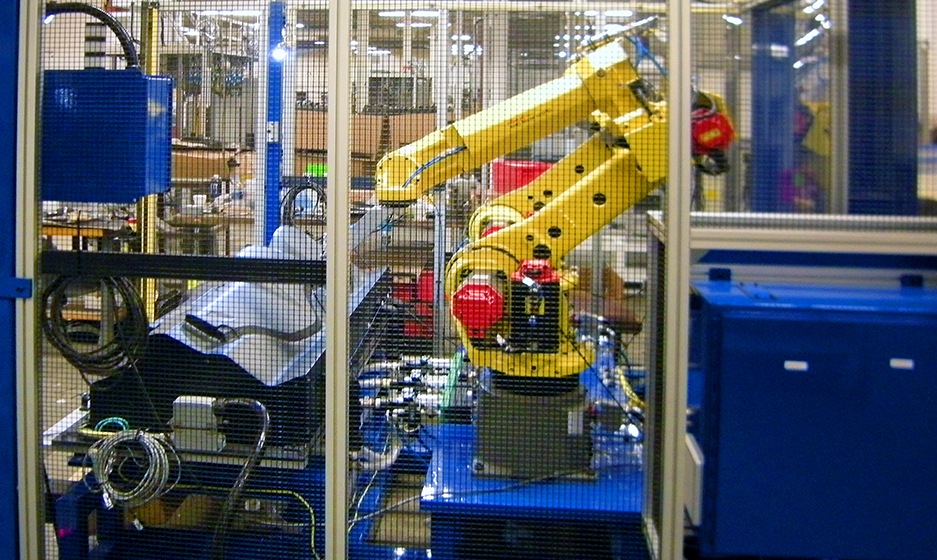

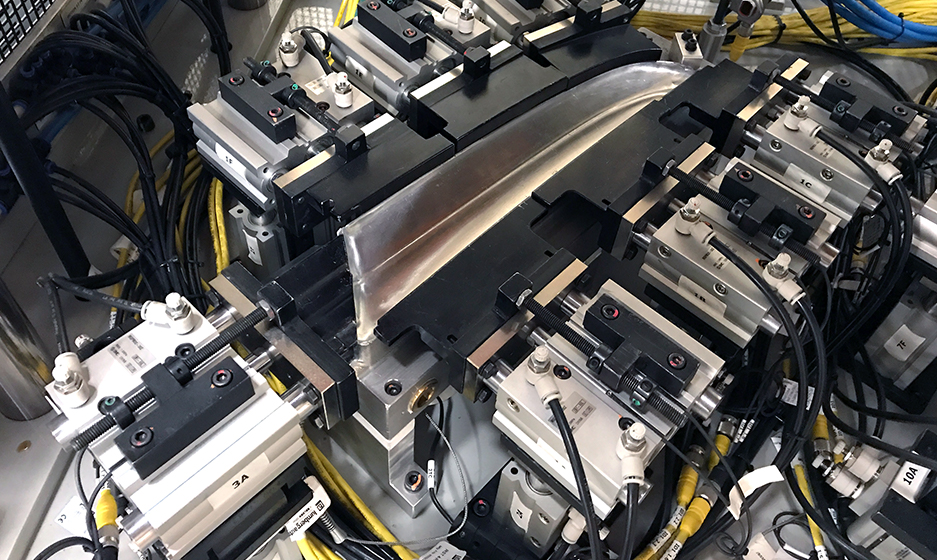

Robotic Clips

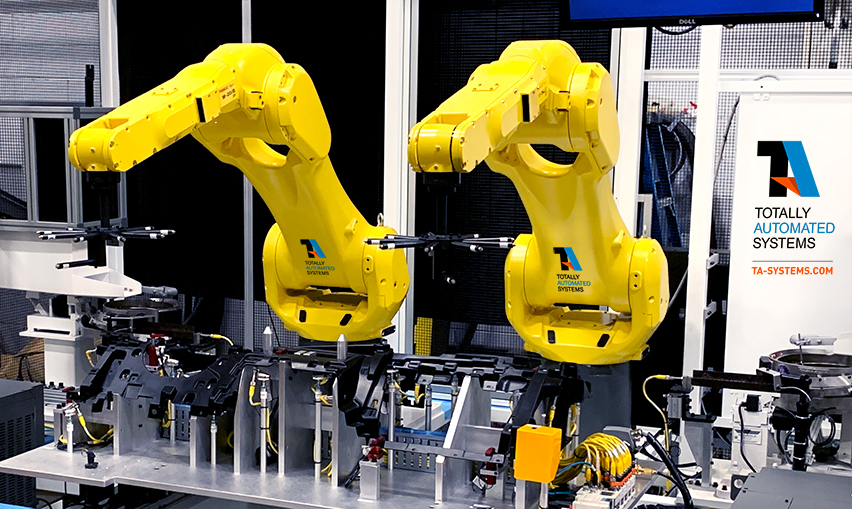

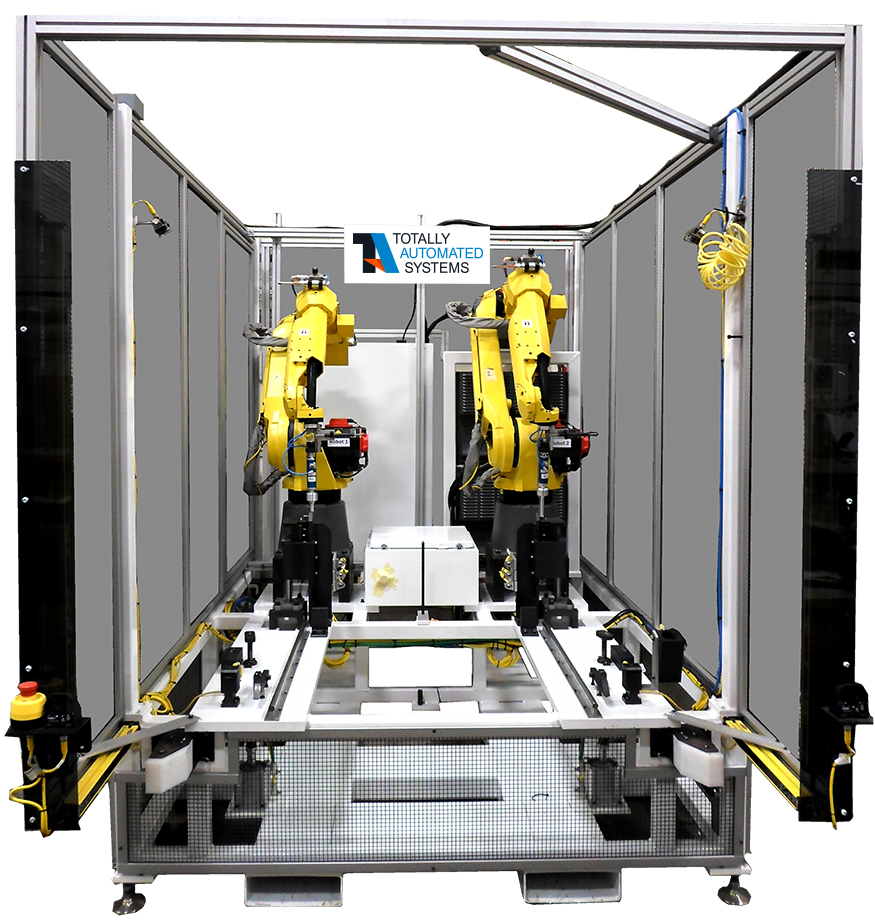

Totally Automated Systems brings over 45 years of expertise in the design and manufacturing of Robotic Clipping Systems for customers in the Automotive Industry.

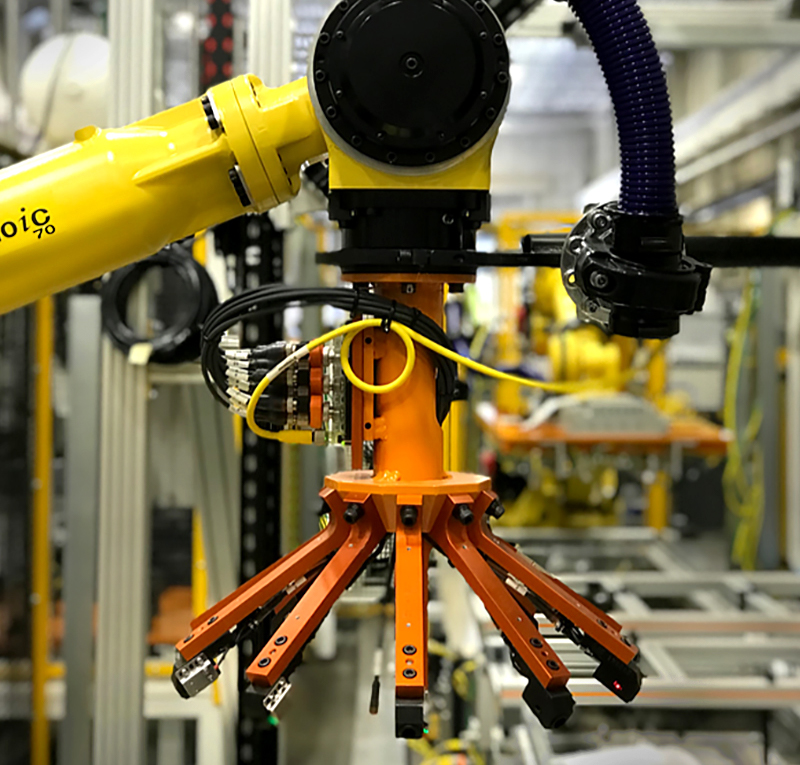

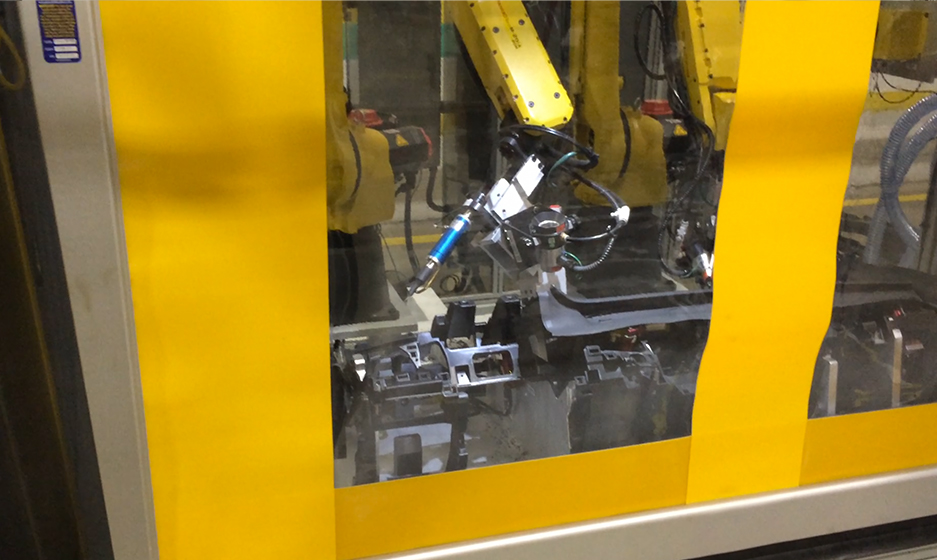

Robotic clipping, also known as robotic clipping or robotic gripper clipping, is a process in industrial automation where robots are used to perform clipping or fastening tasks. This involves using robotic arms equipped with specialized grippers or end-effectors to securely attach or fasten objects together, typically using clips, clamps, or similar fasteners.

In manufacturing and assembly operations, robotic clipping is commonly used in industries such as automotive, electronics, aerospace, and consumer goods. The robots are programmed to precisely position the parts to be clipped together and then use the grippers to apply the necessary force to secure them in place.

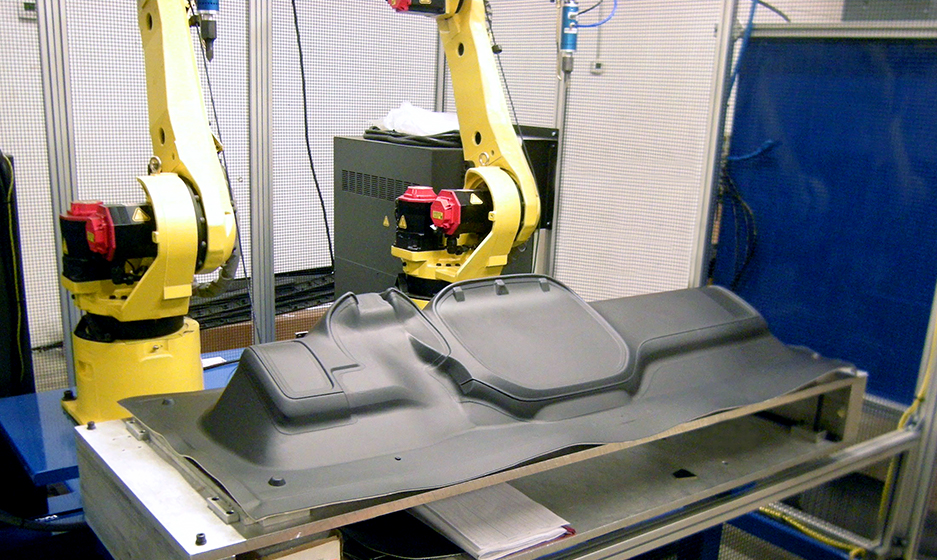

Robotic clipping offers several advantages over manual clipping or other traditional methods of fastening, including increased speed, precision, and consistency. It can also help reduce labor costs, minimize errors, and improve overall production efficiency.

Overall, robotic clipping plays a crucial role in streamlining assembly processes and enhancing productivity in various manufacturing environments.

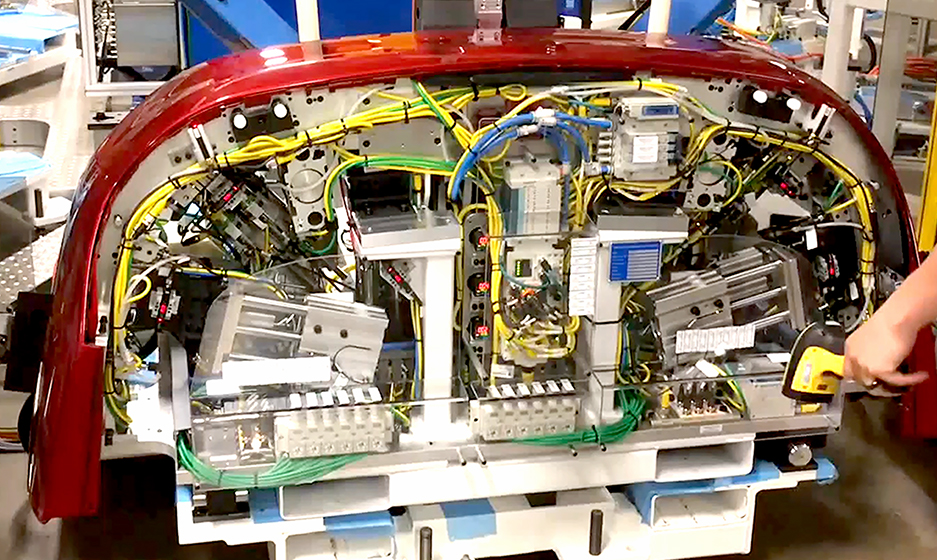

- Fixed or Removable Tool Sets

- Mole Side Installation (with Part Cooling)

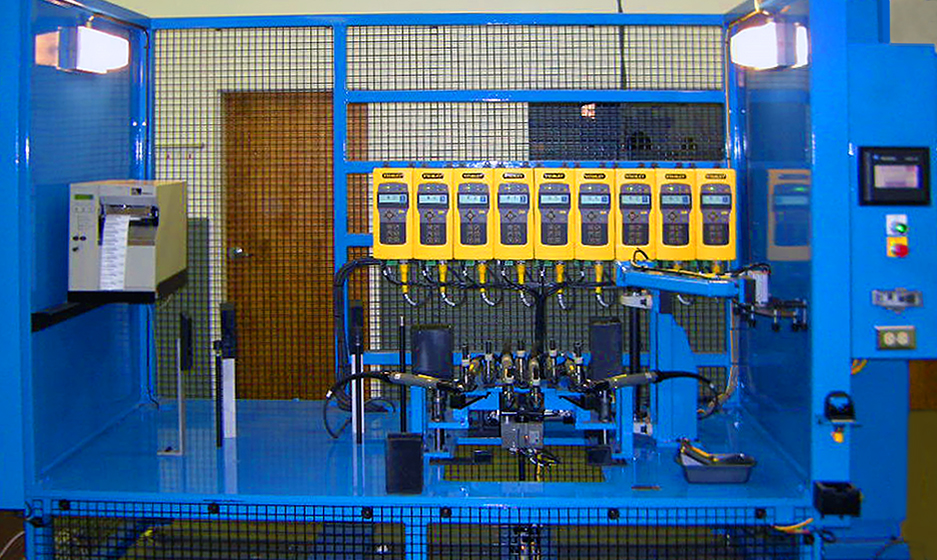

- Manual or Robotic Auto-Feed

- Push Nut Insertion

- Product Flexibility

- Reduction in Future Capital

- Dedicated Equipment

- Robotic Dedicated Equipment

- Tool Exchange Equipment

- Robotic & Flexible Equipment

- Assembly Line Equipment

- Clipping

- Material Handling

- Automotive Interior

- Automotive Exterior