TA Systems Vision Applications

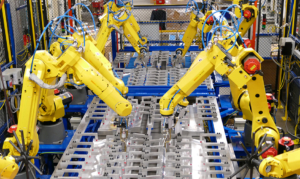

Machine vision systems have revolutionized automated inspection and quality control across various industries. The integration of smart cameras, both 2D and 3D, has significantly enhanced the capabilities of automated systems in production lines.

TA Systems offers key features and applications of machine vision systems:

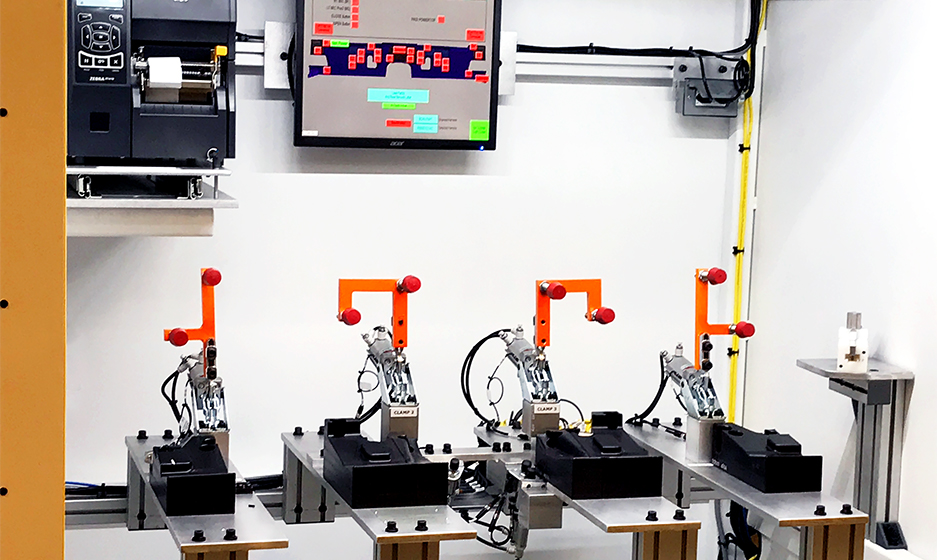

- Automated Inspections: Smart cameras with machine vision capabilities can perform inspections automatically, detecting defects, inconsistencies, or deviations from predefined standards as products move along the production line.

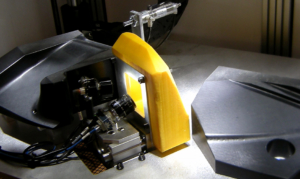

- Robot Guidance: Machine vision systems play a crucial role in guiding robots in tasks such as pick-and-place operations, assembly, and other intricate tasks requiring precision and accuracy.

- Product Sorting: Our systems enable real-time sorting of products based on predefined criteria, ensuring only products meeting quality standards move forward in the production process.

- Quality Control: We facilitate comprehensive quality checks by examining various aspects of products, ensuring they meet specific quality parameters and standards.

- Identification and Recognition: TA Systems machine vision systems can identify objects, codes, or labels, enabling accurate tracking, verification, and authentication of products.

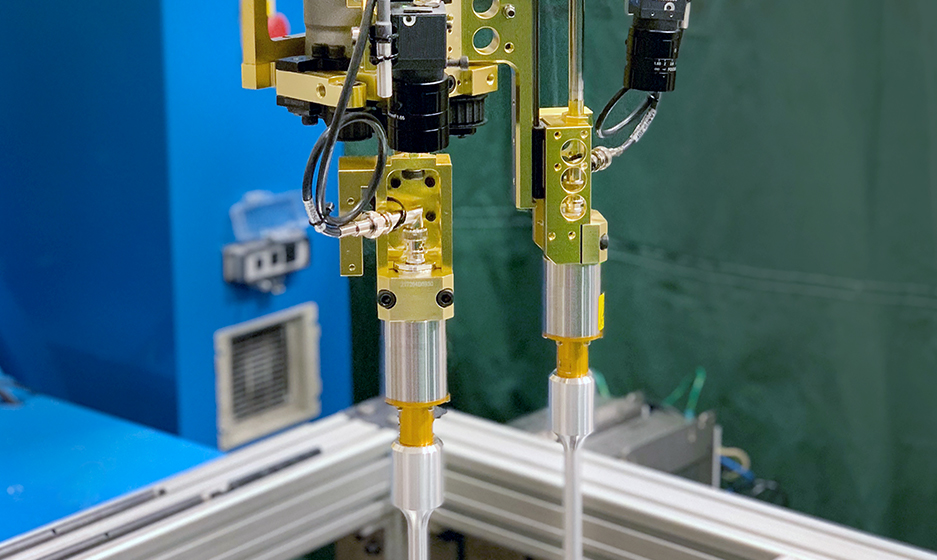

- Measurements and Dimensional Checks: Utilizing 3D cameras, these systems can perform accurate measurements and dimensional checks on products, ensuring they meet precise specifications.

- Adaptive and Learning Capabilities: Our advanced systems incorporate machine learning algorithms to adapt and improve over time, continuously enhancing accuracy and efficiency.

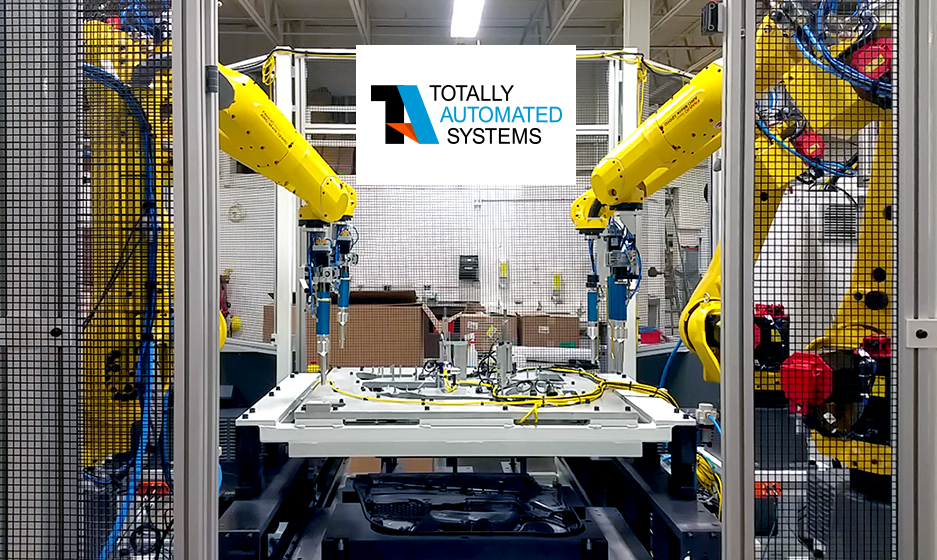

TA Systems provides the ability to calibrate these systems for specific tasks and integrate them seamlessly into production lines has significantly improved operational efficiency, minimized errors, reduced waste, and ensured higher quality outputs.

As technology advances, machine vision systems continue to evolve, we strive to offer more sophisticated capabilities, higher resolutions, and increased accuracy, further contributing to streamlined manufacturing processes across industries.